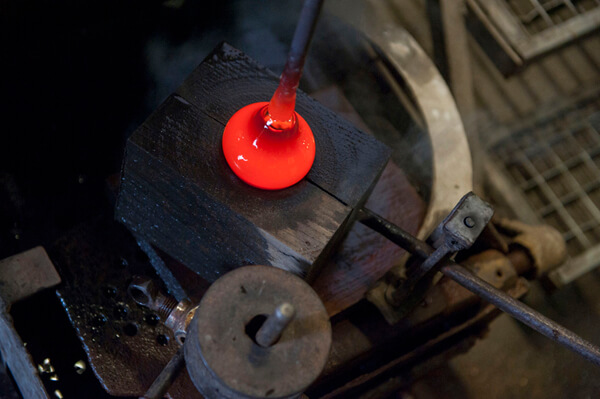

Blowpipe in the furnace

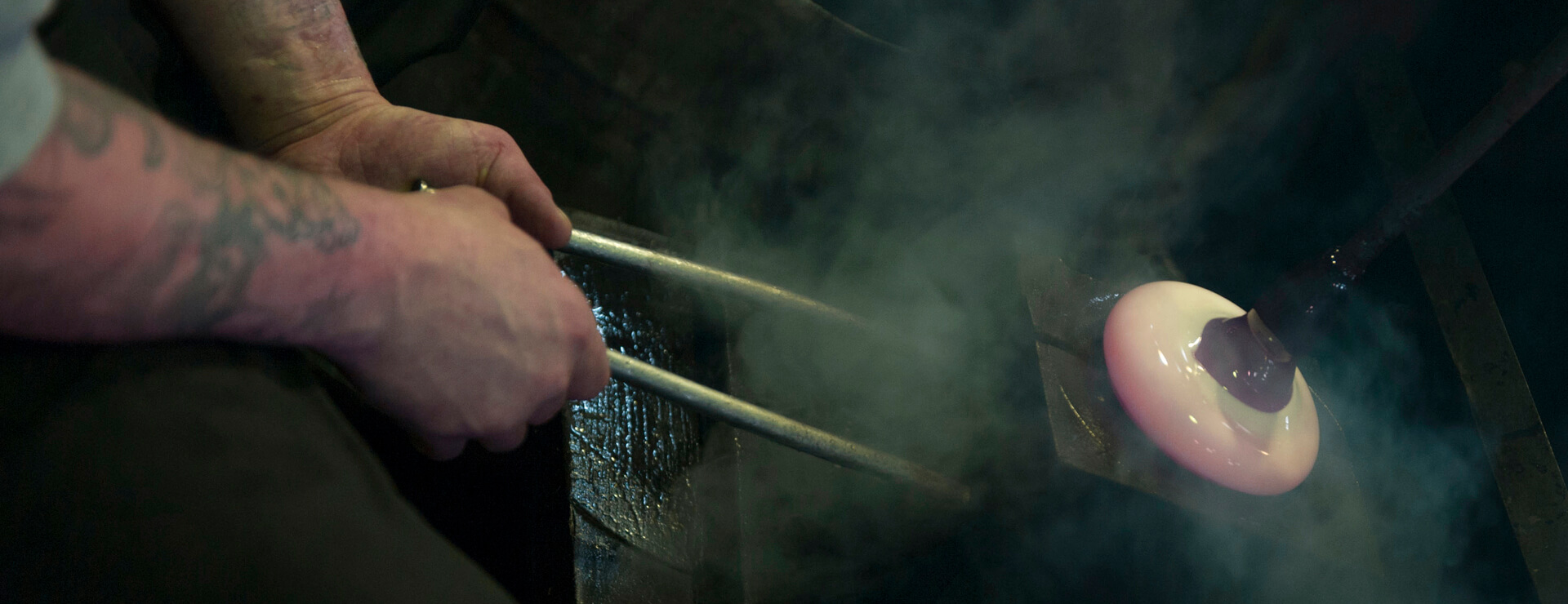

Wooden mold

Glass blown into a wooden mold

As a special variant, so-called “optical- bubbles” demonstrate a very old technique unique to the traditional craftsmanship of OERTEL. The preparation of these ‘optically blown‘ pieces places a high demand on the glassmakers‘ skill, and years of experience are required. The glass is already decorated and still hot. The cased glass with hot ‘gather‘ is lowered into a ribbed or patterned cylindrical shape, and then inflated just so far as to allow the pattern of the preform to be imprinted in the product. The more malleable crystal glass is then blown carefully into its final shape in the flask; this the pre-embossed pattern is obtained. A rapid rotation allows the ribbing to be twisted in spirals, creating fascinating crystal works of art.

The basic shape of our “Amelie” and “Stella” collections, are made using this rare technique. They will enchant you with their exceptional aspect and brilliant effects, enhanced by fine decoration.

Manufacture – click to navigate: